Intelligent equipment

Yejing, being specialized in the design and manufacture of Aluminum extrusion equipment

New type short-stroke press

5500T short-stroke press

1.Shorter dead cycle time, higher production efficiency.

2.The billet pushing system is controlled by servo motor, and the whole billet feeding operation is more rapid, accurate and reliable.

3.The container heating mode adopts direct heating with plug-in heating tube with better heat efficiency and shorter heating time.

4.Designed with square butt shear, it not only improves the shearing precision, but also makes the installation and maintenance of the pressing assemble and the butt shear more convenient.

5.The pre-stressed frame structure greatly reduces the elastic deformation of extrusion.

6.The length of the tie rod and the main cylinder is shortened, and the accuracy and stability of the main frame of the extrusion press are improved.

7.The hydraulic oil required for the machine is reduced and the working cost is lower, the whole machine is more eco-friendly.

-

①

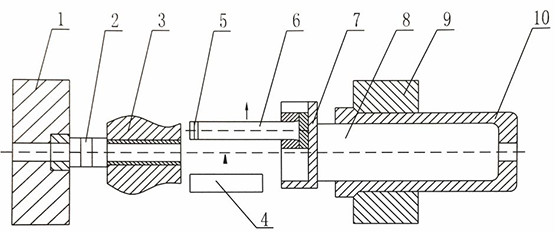

Structural form of back loading short stroke press

Figure 1 Schematic diagram of back loading short stroke press

1.Front platen 2.Die 3.Container 4.Billet 5.Fixed dummy block

6.Extrusion rod 7.Movable cross head 8.Main cylinder plunger 9.End platen 10.Main cylinderAs shown in Figure 1, the action sequence of the back loading stroke aluminum extrusion press is: the extrusion stem moves away from the extrusion center line, the feeding rod position is reserved, the billet feeding device sends the billet to the extrusion center line and pushes the billet into the container, the billet feeding device returns to the extrusion center line after the billet feeding device leaves the rear extrusion rod, the main plunger drives the extrusion rod to move forwards and then begins extrusion.

The billet requirement of back loading short stroke press is not very high, it can suitable to use the billet cut by hot log shear, two small pieces billet together. This structure is suitable for medium and small tonnage presses. -

②

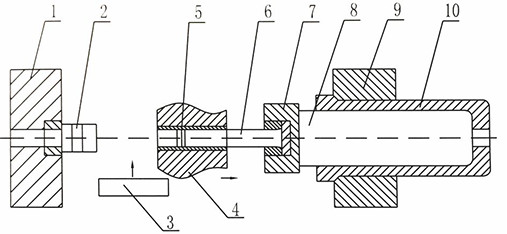

Structural form of front loading short stroke press

Figure 2 Schematic diagram of front loading short stroke press

1.Front platen 2.Die 3.Billet 4.Container 5.Fixed dummy block

6.Extrusion rod 7.Movable cross head 8.Main cylinder plunger 9.End platen 10.Main cylinderAs shown in Figure 2, the action sequence of the front loading short stroke extrusion press is: the main plunger and container are retracted until the feeding billet position is reserved between the container and the mould, the billet feeding delivery the billet to the press center line, the container moves forward and sleeves with the aluminum rod, and finally, the main plunger plug drives the extrusion rod to move forward and then starts to extrusion

The billet requirement of front loading short stroke press is very high,the billet is only suitable to cut by hot saw or cool saw. This structure is suitable for the bigger tonnage presses.